Light Negative Oxygen Ions Technology (LNOI) is an innovative technology. It combines sunlight and negative oxygen ions. This technology aims to create a healthy, fresh, and efficient air environment. It does so by simulating sunlight and forest negative oxygen ions found in the natural environment. This technology has been widely used in air purification, sterilization and disinfection, healthy lighting and other fields.

The core principle of photonegative oxygen ion technology is to combine “light elements” with “negative oxygen ion elements.” These elements include visible light, infrared light, and ultraviolet light. A spectrum of specific wavelengths is used to excite oxygen molecules in the air. This process generates negative oxygen ions. These negative oxygen ions can actively adsorb bacteria, viruses, pollen, dust, and other harmful substances in the air. They purify the air. At the same time, they decompose ozone ions to prevent harm to the human body.

Four core functions

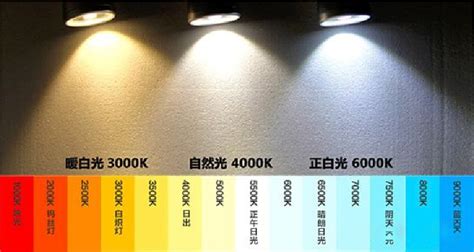

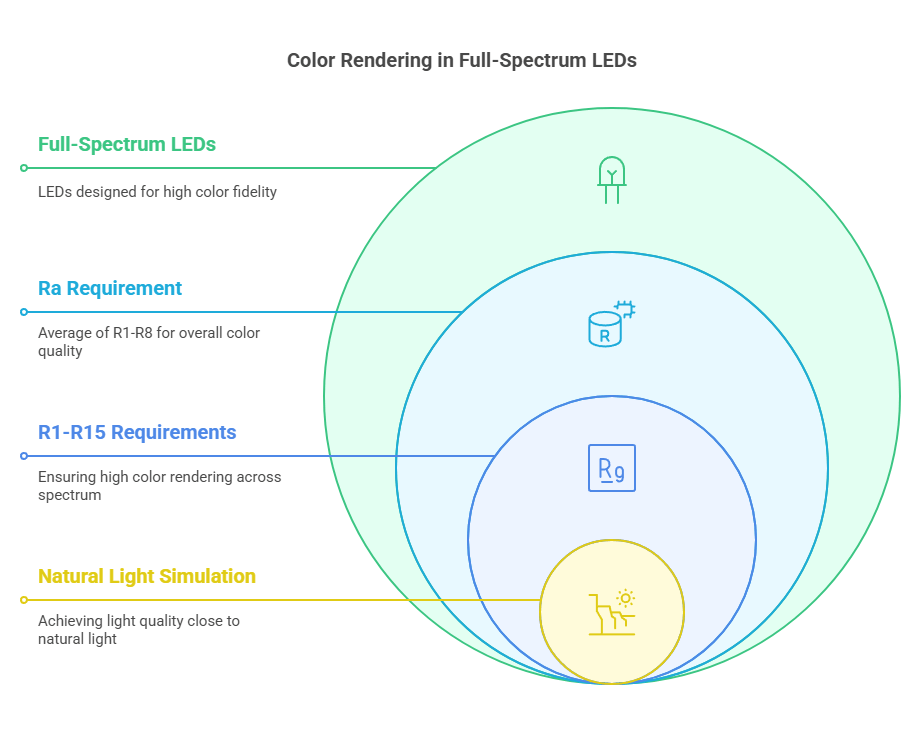

- Healthy Light: Simulates the spectrum of sunlight. It includes the addition of R9 red light and IR infrared spectrum. These can help delay myopia and combat depression. They also improve sleep quality.

- Forest Oxygen Bar: Simulates the negative oxygen ion environment in the forest, releases high concentration of negative oxygen ions (2500 per cubic centimeter≥ to create fresh air similar to a natural forest.

- Air purification: Adsorb suspended impurities and bacteria in the air through negative oxygen ions, effectively remove formaldehyde, PM2.5 and other pollutants, and improve indoor air quality.

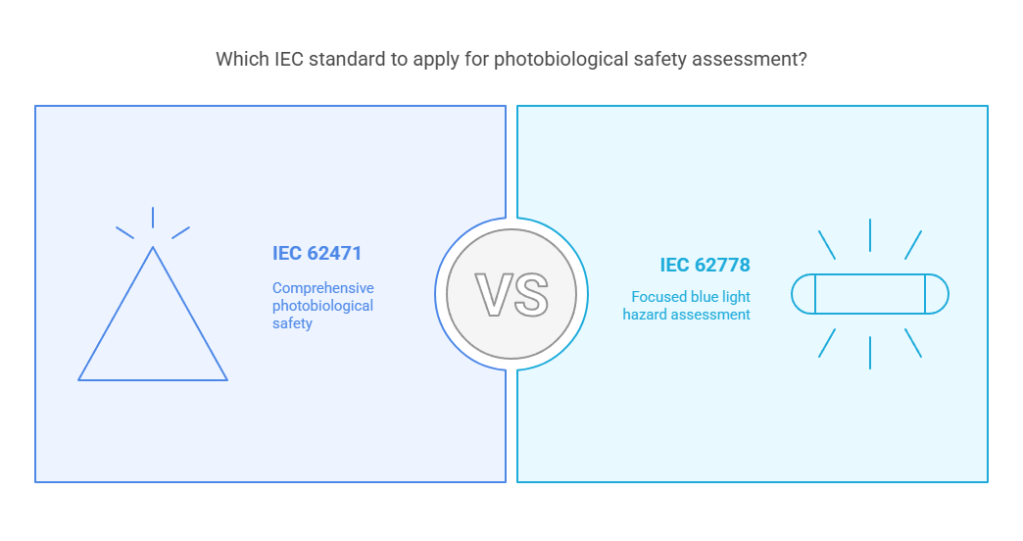

- Sterilization and disinfection: The ultraviolet spectrum, such as UVC, utilizes a specific wavelength band. It simulates the sterilization function of natural sunlight. This method efficiently kills bacteria, viruses, and other microorganisms.

Technical Features & Benefits:

- Safety: The photonegative oxygen ion technology has been scientifically verified. It ensures that it meets the technical specifications of electromagnetic radiation and electromagnetic interference when working. It is harmless to the human body.

- Versatility: The technology purifies the air. It sterilizes and disinfects. Additionally, it provides healthy lighting to offer users comprehensive health protection.

- Environmental protection: The photonegative oxygen ion technology is powered by green energy. It does not produce pollutants such as waste water and exhaust gas.

Application ScenarioPhotonegative oxygen ion technology is widely used in various electrical products. These include air purifiers, lamps, air conditioners, and washing machines. For example, in air purifiers, it effectively removes formaldehyde, ammonia, and hydrogen sulfide. In the luminaire, it combines the LED light source to release negative oxygen ions. This provides healthy lighting. In air conditioning, it mitigates renovation pollution. It also improves indoor air quality.

SummaryPhotonegative oxygen ion technology is advanced. It integrates sunlight and negative oxygen ions. This technology realizes many functions such as air purification, sterilization, disinfection, and healthy lighting. It does so by simulating sunlight and forest negative oxygen ions in the natural environment. This technology can not only improve air quality, but also provide users with a healthy living and working environment, which is an important environmental and health solution in modern life